Our partner network

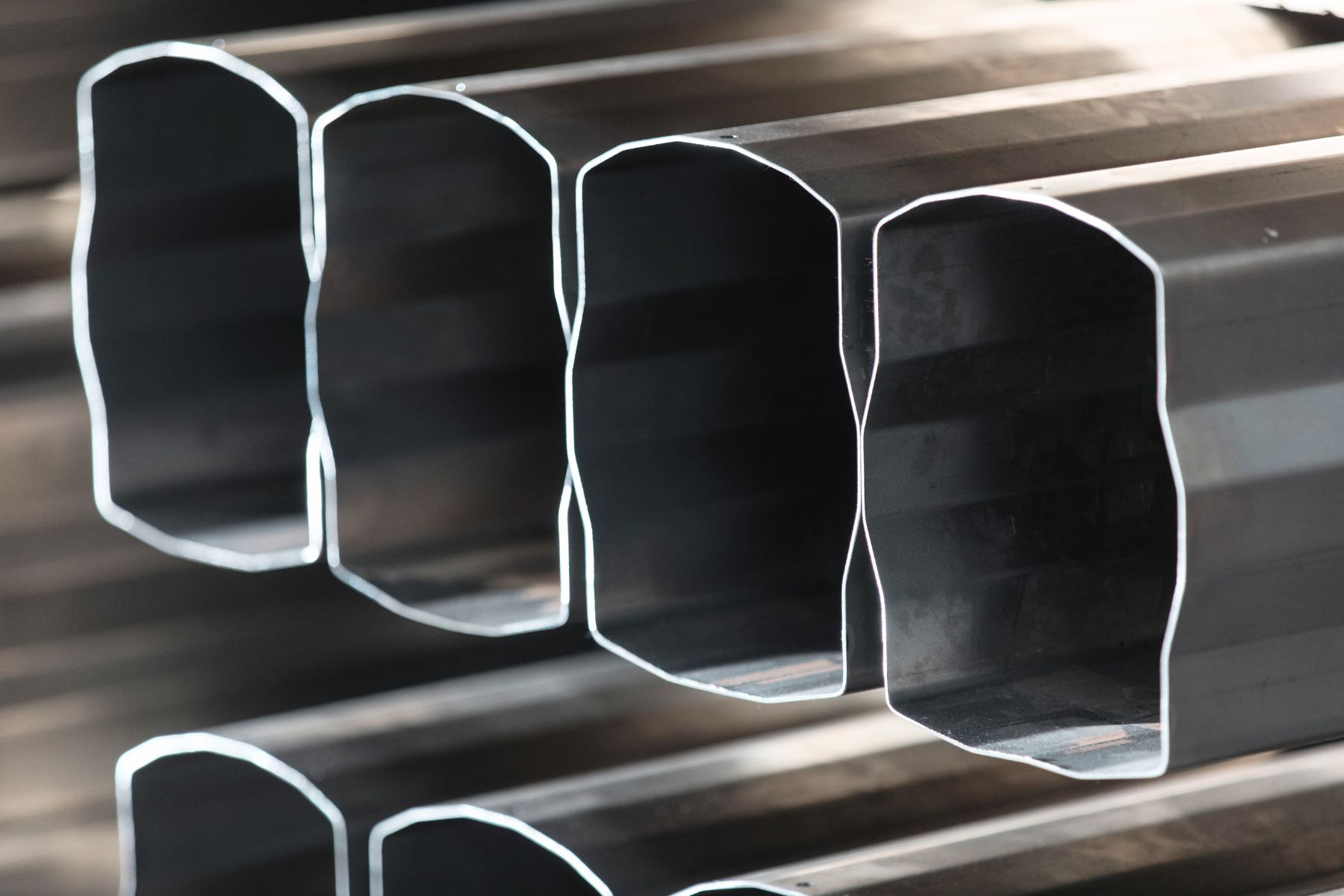

- Specialised in components made from high-strength fine-grained steels

- Partner company for welding telescopic booms with a load capacity of 160 to 1,200 tons

- Material thicknesses from t = 4 mm

- Partly and fully mechanised welding processes

- More than 27 years experience

- System supplier for steel components

- Partner company for welding, including high-strength steels, with all certifications

- From sheet metal management, cutting, assembly and welding through to mechanical treatment and surface technology

- Experience since 2008

- Specialised in welding assembly groups

- For high-tensile and wear resistant grades

- Experience in especially thin metal sheets used in the height access technology

- Reacts especially fast and flexibly

Partner company for mechanical processing and drill centre machining

- State-of-the-art machinery

- More than 20 years of experience

- Inclusive company

- Employs both able-bodied and handicapped staff

Partner company for drill centre machining

- Specialised in large assembly groups

- Market-leading in mechanical processing of large parts

- Possible component lengths: up to 24 metres

- More than 15 years of experience

Partner company for metal and steel construction

- Single unit and large serial production

- High-precision CNC processing

Tailor-made solutions

Partner company for small component production

- Ultra-modern machinery

- Thermal cutting up to at material thickness of 110 mm

- Metal forming up to 4,000 mm in length

- Metal machining service

- Founded in 2020